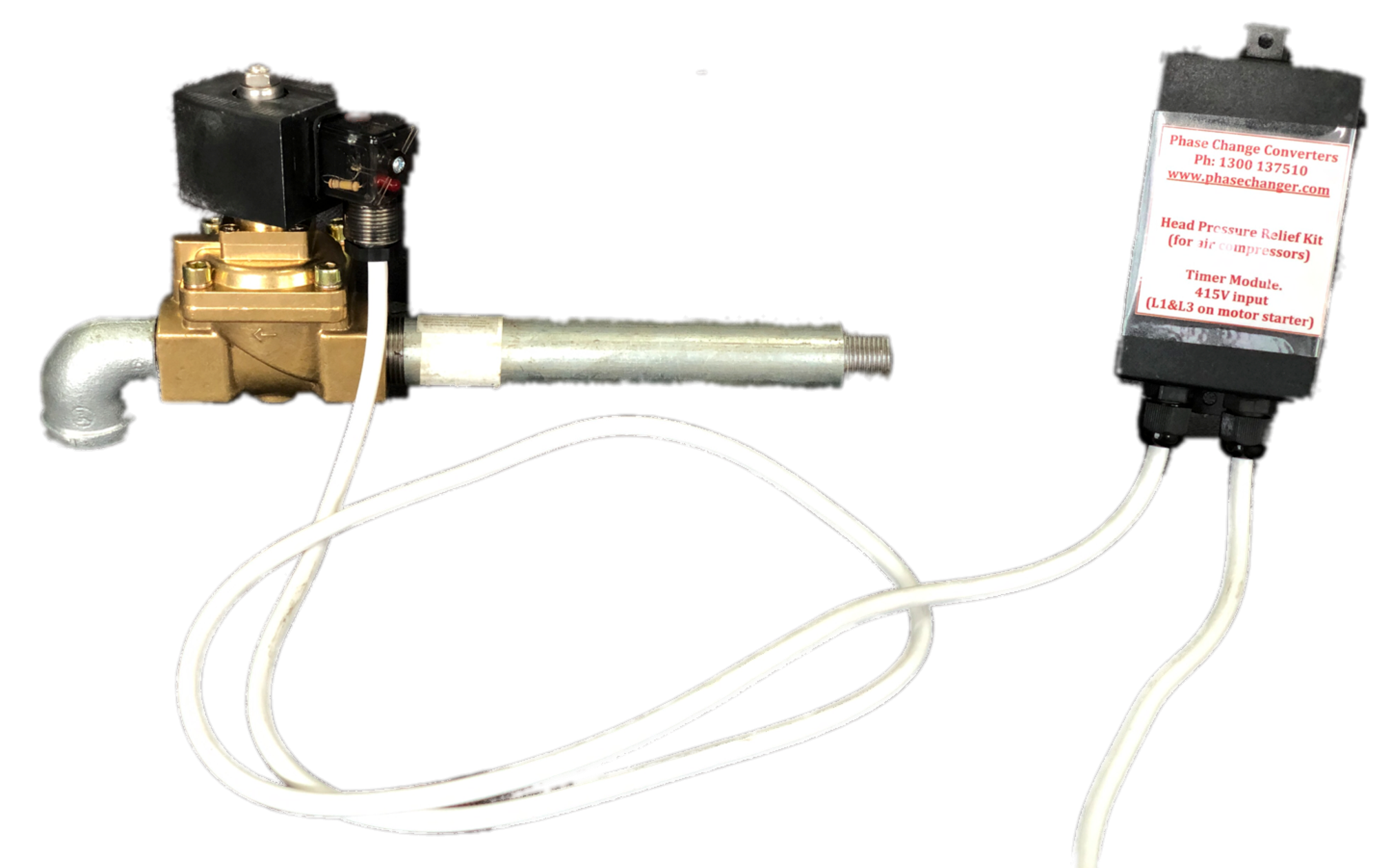

Compressor Head Pressure Relief Kit

The head pressure relief kit can be adapted to suit any 3 phase compressor and significantly reduces the start up current required to get the compressor up and running. Compressors typically require much more power to start once the tank has been filled and has been bled off to cut-in pressure point which may often be 80-90psi.

Unfortunately the mechanical valve system fitted to many compressors as standard does no more than empty the airline between the compressor head and the tank, which can literally refill within a few strokes of the compressor restarting, and is often not long enough to get the motor fully up to speed.

An electric motor can draw up to 600% its normal running current when it is below full speed, so the quicker it can get to full speed, the less inrush current is required and the less impact there is on the electrical mains.

This is particularly important when a larger 3 phase compressor is being supplied from a Phase Change Converter, as ultimately that start up energy must be drawn from the single or two phase incoming mains, which may be limited in it’s ability to provide enough power for a clean start up of the compressor.

Real world testing, has demonstrated that the addition of the head pressure relief kit to a compressor can reduce inrush current by as much as 50%, which usually solves start up issues where there is a marginal single or two phase supply feeding a Phase Change Converter.

OPERATION:

The solenoid will open to atmosphere whenever the motor is not running and for approx 5 seconds at startup, ensuring there is no head pressure to pump against, significantly reducing the mechanical starting load on the motor.